-

xingyu

Hi there! Welcome to my shop. Let me know if you have any questions.

xingyu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

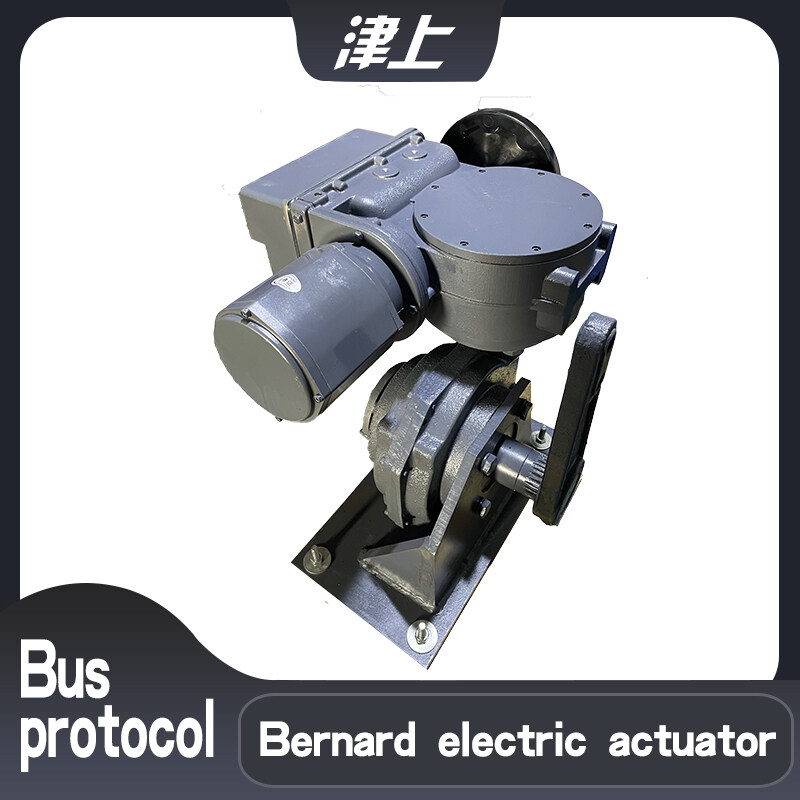

Performance comparison of cylinder and electric actuator

2021-11-29 09:02:42

Compared with the electric actuator, the cylinder can work under harsh conditions, and the operation is simple, and can basically achieve maintenance-free. Cylinder is good at reciprocating linear motion, especially suitable for industrial automation transmission requirements - linear handling of the workpiece. Moreover, adjusting the one-way throttle valve installed on both sides of the cylinder can easily achieve stable speed control, which also becomes the feature and advantage of the cylinder drive system. So for users who do not have the requirements of multi-point positioning, most of them prefer to use cylinders from the perspective of convenience. Most of the applications of electric actuators in the industrial field require precision multi-point positioning, which is the result of poor implementation with cylinders.

The electric actuator is mainly used for rotation and swing conditions. Its advantage lies in fast response time and accurate control of speed, position and torque through feedback system. However, when it is necessary to complete the linear movement, it is necessary to carry out the transmission transformation through the gear belt or screw and other mechanical devices, so the structure is relatively complex, and the working environment and the professional knowledge of operation and maintenance personnel have higher requirements.

The advantage of the cylinder is that

(1) Lower requirements for users. The principle and structure of the cylinder are simple, easy to install and maintain, and the requirements for users are not high. Electric cylinder is different, engineers also need to have some electrical knowledge, otherwise it may be damaged because of misoperation.

(2) Large output force. The output force of the cylinder is proportional to the square of the cylinder diameter; The output force of electric cylinder is related to three factors, cylinder diameter, motor power and screw pitch. The larger the cylinder diameter and power, the smaller the pitch, the greater the output force. A cylinder diameter of 50mm, the theoretical output force can reach two thousand NM, for the same cylinder diameter of the electric cylinder, although different companies have different products, but basically no more than one thousand N. Obviously, the cylinder has the advantage in terms of force output.

The advantages of electric cylinder are mainly reflected in the following three aspects:

(1) The system structure is very simple. Because the motor is usually integrated with the cylinder block, plus the controller and cable, the whole system of the electric cylinder is composed of these three parts, simple and compact.

(2) The number of stop positions and high control accuracy. Low-end products can be stopped at 3, 5, 16, 64, etc., which varies according to different companies. Products can reach hundreds or even thousands of locations. In terms of accuracy, electric cylinder also has great advantages, positioning accuracy can reach 0.05mm, so it is often used in electronics, semiconductor and other precision industries.

(3) Good flexibility. An electric cylinder is much more flexible than a cylinder. Because the controller can be directly connected with PLC, the motor speed, positioning and positive and negative rotation can achieve accurate control, in some extent, the electric cylinder can according to the need for arbitrary movement; Because of the compressibility of the gas and the inertia generated when moving, even a good match between the reversing valve and the magnetic switch cannot achieve accurate positioning of the cylinder, and flexibility is out of the question.

-

K30 Soil Testing Equipment Supplier K30 Load Tester for Sale K30 Tester Manufacturer

-

Geotechnical K30 Plate Load Tester Buy K30 Automatic Load Tester K30 Plate Load Tester Price

-

Soil Compaction Test Equipment K30 Foundation Testing K30 Load Plate Road Construction K30 Testing Machine

-

K30 Modulus Test Machine K30 Bearing Capacity Test Apparatus K30 Tester for Civil Engineering

-

Automatic Data Logging K30 Tester Portable K30 Plate Load Tester K30 Soil Stiffness Measurement Device

-

Automatic K30 Soil Bearing Capacity Tester K30 Static Plate Load Test Device Digital K30 Load Test Equipment

-

K30 Soil Testing Equipment Supplier K30 Load Tester for Sale K30 Tester Manufacturer

-

Geotechnical K30 Plate Load Tester Buy K30 Automatic Load Tester K30 Plate Load Tester Price

-

Soil Compaction Test Equipment K30 Foundation Testing K30 Load Plate Road Construction K30 Testing Machine

-

K30 Modulus Test Machine K30 Bearing Capacity Test Apparatus K30 Tester for Civil Engineering

-

Automatic Data Logging K30 Tester Portable K30 Plate Load Tester K30 Soil Stiffness Measurement Device

-

Automatic K30 Soil Bearing Capacity Tester K30 Static Plate Load Test Device Digital K30 Load Test Equipment

-

Intelligent K30 Load Tester Flat Plate Load Tester

-

EV2 modulus tester for civil engineering Laboratory and field EV2 testing machine EV2 vs. EV1 modulus testers

-

Soil stiffness testing machine High-precision EV2 Static Deformation Modulus Tester Portable plate load test equipment EV2

-

Static Plate Load Test for soil compaction Deformation modulus measurement device Geotechnical testing equipment EV2

-

Static Deformation Modulus Tester for sale EV2 Plate Load Test Machine EV2 Test according to DIN 18134

-

Buy EV2 Static Plate Load Tester EV2 Modulus Tester price EV2 Testing Equipment suppliers

-

Plate Bearing Test Apparatus Static Deformation Modulus Test (EV2)

-

EV2 Static Deformation Modulus Tester Static Plate Load Test Equipment EV2 Modulus Testing Machine

-

spring fatigue testing machine manufacturers Spring fatigue testing machine suppliers OEM spring fatigue tester

-

Custom spring fatigue endurance tester Buy spring fatigue testing machine Spring fatigue tester price list

-

High-temperature spring fatigue testing machine Spring fatigue test machine with force measurement Multi-station spring fatigue testing system

-

DIN 50100 spring endurance tester JIS B 2704 spring fatigue testing machine Spring fatigue tester with environmental chamber